Transforming the Future of Urban Maintenance: The Role of 3D Printing in Manufacturing Road Sweeper Trucks

In today’s fast-evolving industrial landscape, 3D printing is unlocking unprecedented opportunities across various sectors, notably in the manufacturing of road sweeper trucks. This revolutionary technology enhances product design, accelerates production timelines, reduces costs, and elevates customization capabilities, positioning businesses like ceksansweepers.com as pioneers in innovative urban maintenance solutions.

Understanding 3D Printing in the Context of Business Innovation

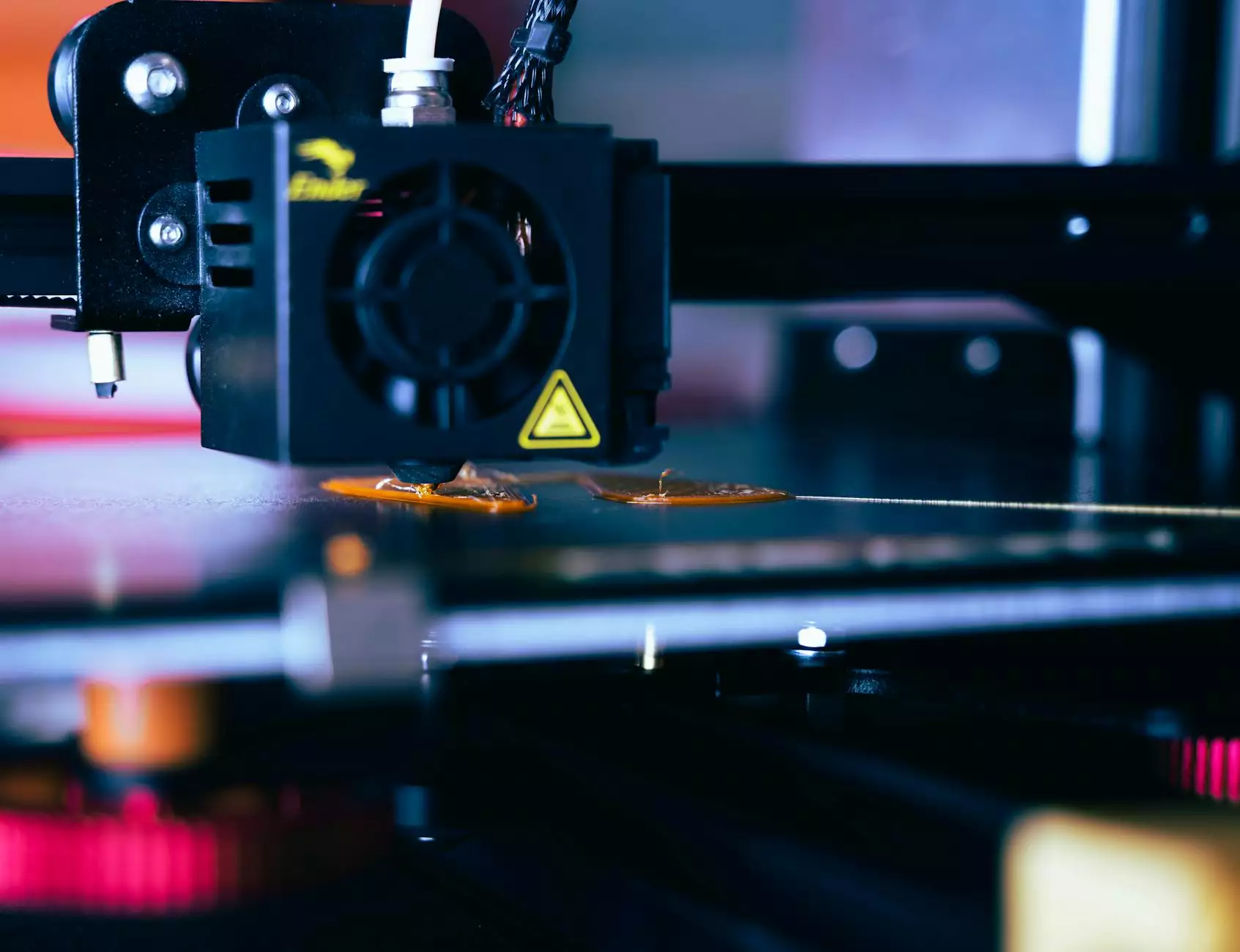

3D printing, also known as additive manufacturing, involves creating three-dimensional objects by layering materials based on digital models. Its integration into business models signifies a paradigm shift from traditional manufacturing processes, emphasizing agility, precision, and sustainability.

- Rapid Prototype Development: Accelerates design testing, allowing for swift modifications and improvements.

- Customized Production: Enables tailored solutions for specific client needs, particularly valuable in specialized vehicles like road sweeper trucks.

- Cost-Efficiency: Reduces material waste and lowers production costs, especially for low-volume or complex components.

- Sustainable Manufacturing: Promotes eco-friendly practices through efficient use of resources.

The Interplay of 3D Printing and Road Sweeper Trucks

At the heart of urban sanitation and street maintenance, road sweeper trucks are vital for maintaining clean, safe, and environmentally friendly city environments. Integrating 3D printing into their design and production processes offers numerous advantages:

Enhanced Customization and Design Flexibility

Urban contexts demand tailored solutions. 3D printing allows manufacturers like ceksansweepers.com to produce road sweeper trucks with customized components that meet specific city requirements—be it tailored brushes, unique hopper shapes, or ergonomic controls. This flexibility ensures optimal efficiency for different urban terrains and maintenance needs.

Rapid Prototyping and Innovation

Thanks to 3D printing, designers can rapidly develop prototypes of road sweeper trucks components, testing new features before mass production. This accelerates innovation cycles, enabling companies to stay ahead in a competitive market and continuously improve their offerings.

Cost-Effective Production of Spare Parts

Rather than maintaining large inventories of spare parts, businesses can print essential components on-demand, reducing storage costs and minimizing downtime during maintenance. This approach ensures that city fleets remain operational with minimal interruption.

Benefits of 3D Printing for Business Growth in Street Maintenance Equipment

The strategic adoption of 3D printing extends far beyond manufacturing. It influences various facets of business growth, including:

- Increased Market Competitiveness: Offering unique, high-quality products with quick turnaround times strengthens market position.

- Enhanced Customer Satisfaction: Customized, reliable, and innovative road sweeper trucks meet customer expectations more precisely, building loyalty.

- Sustainable Business Practices: Reducing waste and energy consumption aligns with global sustainability goals, appealing to eco-conscious clients.

- Reduced Time-to-Market: Faster development cycles mean quicker entry into new markets or sectors.

Future Trends: How Road Sweeper Trucks Will Evolve with 3D Printing

Looking ahead, the synergy between 3D printing and road sweeper trucks promises to revolutionize urban sanitation further with trends such as:

- Smart Components Integration: Embedding sensors and IoT devices printed through advanced methods for real-time monitoring and maintenance.

- Lightweight yet Durable Materials: Using innovative materials to reduce vehicle weight, increasing efficiency, and lowering fuel consumption.

- Decentralized Manufacturing: Small-scale 3D printing facilities close to urban centers for faster response and customization.

- Sustainable Material Adoption: Transitioning towards biodegradable or recycled materials for environmentally responsible manufacturing.

Why Choose Ceksan Sweepers for Your Business Needs

Ceksan Sweepers exemplifies innovation in the 3D Printing of road sweeper trucks. Their commitment to cutting-edge technology, quality craftsmanship, and customer-centric solutions ensures urban infrastructure remains efficient and environmentally sustainable.

They leverage 3D printing to develop:

- Customizable components tailored to diverse city requirements

- Rapid prototyping capabilities for ongoing product improvement

- Efficient spare parts production, minimizing downtime

- Eco-friendly manufacturing practices aligned with global sustainability initiatives

Key Takeaways for Business Success in the Sector

For companies aspiring to lead in the manufacturing and service provision of road sweeper trucks, embracing 3D printing is not just advantageous but essential. Here are strategic benefits to integrate:

- Invest in Modern Technology: Equip your production lines with advanced 3D printers capable of handling diverse materials.

- Focus on Customization: Develop flexible design processes that accommodate client-specific needs.

- Adopt Sustainable Practices: Prioritize eco-friendly materials and processes to align with environmental standards.

- Enhance R&D Capabilities: Foster innovation through rapid prototyping and iterative testing.

The Economic Impact of 3D Printing in Urban Infrastructure Maintenance

The adoption of 3D printing in manufacturing road sweeper trucks generates significant economic benefits. It reduces production and inventory costs, cuts lead times, and enables more competitive pricing. Moreover, it stimulates local economies through decentralization and fosters new jobs in design, engineering, and digital manufacturing sectors.

Conclusion: Embracing Innovation for a Cleaner, Smarter Future

In the realm of urban street maintenance, 3D printing is revolutionizing how road sweeper trucks are designed, produced, and maintained. It empowers businesses like ceksansweepers.com to lead with innovative, sustainable, and customized solutions that meet the demands of modern cities. As urban environments continue to grow and evolve, embracing such advanced manufacturing technologies will be critical for maintaining competitive edge, achieving operational excellence, and supporting sustainable urban development.

Business leaders committed to innovation should actively explore and integrate 3D printing into their manufacturing strategies—paving the way for smarter, cleaner, and more efficient city infrastructure solutions.