The Ultimate Guide to Powder Booths in the Automotive Industry

Understanding Powder Booths: A Crucial Component in Automotive Painting

In the fast-paced world of automotive manufacturing, the powder booth stands as a pivotal element in achieving superior paint finishes. Unlike traditional liquid painting methods, powder coating offers numerous advantages, making it a popular choice in the automotive industry. This article delves into the intricacies of powder booths, exploring their functionality, benefits, and considerations for businesses like autocoatindia.com operating in the automotive paint and sip sectors.

What is a Powder Booth?

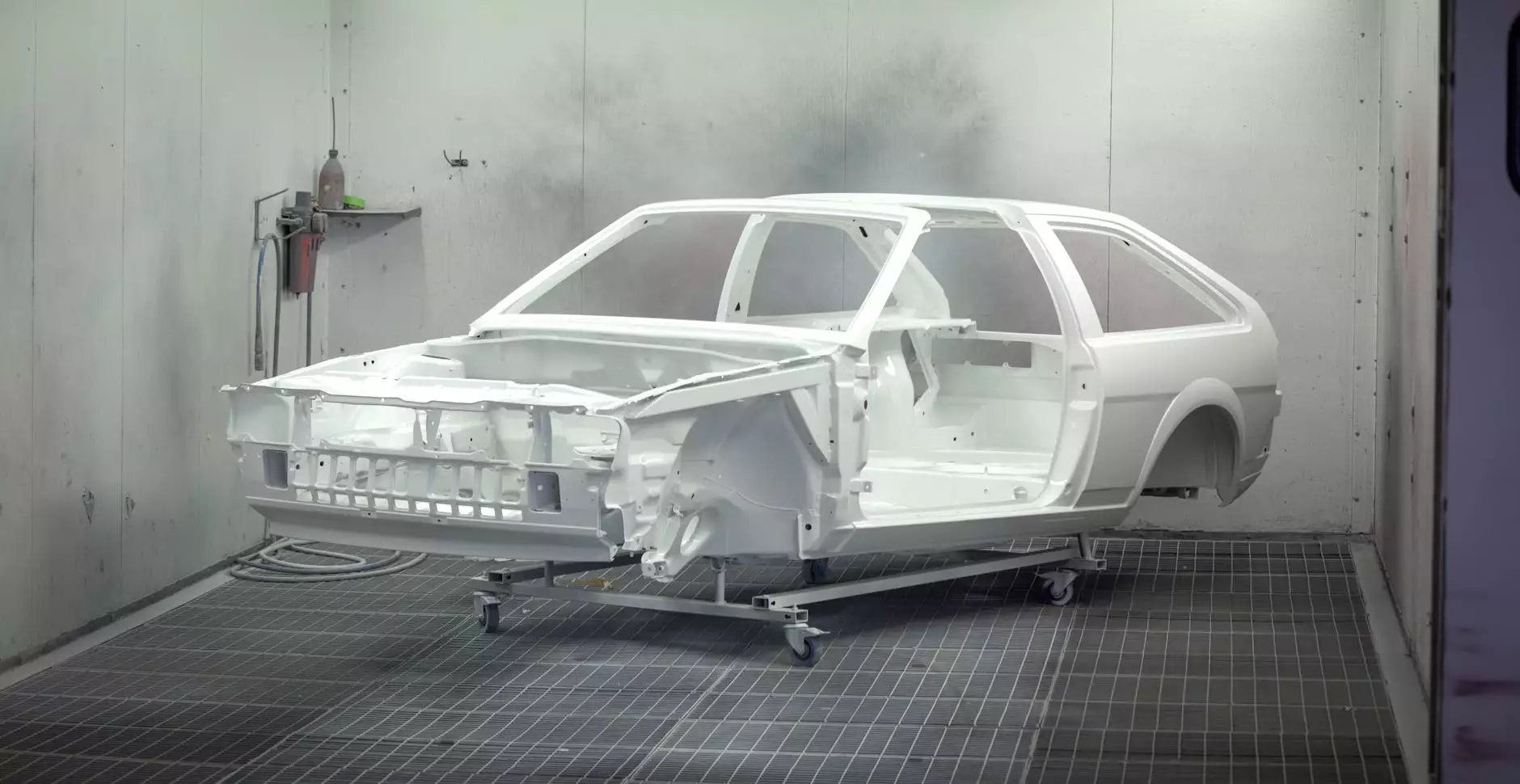

A powder booth is a specialized environment designed for applying powder coatings to various surfaces, particularly in the automotive sector. The booth is equipped with advanced technology that ensures an even distribution of powder particles on the vehicle's surface, ultimately promoting a flawless finish.

How Do Powder Booths Work?

The process begins with the careful preparation of the vehicle's surface, often involving cleaning and treating to remove any impurities. Once prepped, the vehicle is placed inside the powder booth, where the powder coating is electrostatically charged. This charge helps the powder particles adhere evenly to the surface. After application, the vehicle is cured in an oven, where the powder melts and forms a durable, protective layer.

The Advantages of Using Powder Booths in Automotive Painting

For companies like Autocoat India, utilizing powder booths comes with a plethora of benefits:

- Eco-Friendly: Powder coatings release minimal volatile organic compounds (VOCs), making them a more environmentally sustainable choice.

- Durability: The finishing produced by powder booths typically withstands chipping, scratching, and fading much better than traditional paint.

- Cost-Effective: With less waste material and reduced energy consumption during the drying phase, powder coating proves to be economically advantageous.

- Flexibility: Powder booths support a wide variety of colors and finishes, accommodating the unique demands of automotive customization.

- Enhanced Productivity: The efficiency of powder application and curing in a controlled environment decreases turnaround times significantly, benefiting automotive production schedules.

Types of Powder Booths

Understanding the different types of powder booths available can significantly help businesses choose the right solution for their needs:

- Manual Powder Booths: Operated by skilled technicians, these booths are versatile and ideal for smaller operations or custom jobs.

- Automated Powder Booths: Integrating conveyor systems, these booths are perfect for mass production environments, providing consistent and efficient coating applications.

- Downdraft Powder Booths: These booths feature a downward airflow, minimizing airborne powder and ensuring an even application while maintaining a clean environment.

- Crossdraft Powder Booths: Utilizing a crossflow for air circulation, these booths are typically more economical but can result in uneven powder application if not managed properly.

Choosing the Right Powder Booth for Your Business

Selecting the right powder booth for your automotive paint operations requires a careful assessment of several factors:

1. Production Capacity

The scale of your operations will significantly influence the type of powder booth you need. Smaller businesses may benefit from manual booths, while larger manufacturers could require automated systems to maintain efficiency.

2. Space Availability

Consider the physical space available in your facility. Ensure that the booth not only fits well but also allows for easy access for loading and unloading vehicles.

3. Desired Finishes

The complexity of finishes you aim to achieve should guide your choice. Some booths offer more customization options than others.

4. Budget Constraints

Analyze your budget to find a balance between quality and cost-effectiveness. The initial investment in a well-constructed powder booth can pay off through long-term savings in materials and labor.

The Impact of Powder Booths on Efficiency and Quality

Investing in a quality powder booth has a transformative impact on production efficiency and finish quality. The modern design of these booths allows for precise control over variables such as:

- Temperature: Optimal heat settings for curing powders ensure that coatings are uniformly applied and adequately set.

- Airflow: Controlled airflow technologies minimize the risk of contamination, leading to cleaner and more efficient applications.

- Electrostatic Charge: The application of a consistent electrostatic charge allows for better powder adherence, resulting in less waste and improved quality.

Maintaining Your Powder Booth for Longevity

Regular maintenance of your powder booth is essential to ensure it performs optimally over its lifetime. Here are some maintenance tips:

- Daily Cleaning: Remove any excess powder and debris to prevent contamination and improve performance.

- Weekly Inspections: Check electrical and mechanical components to identify wear and resolve issues before they escalate.

- Filter Replacements: Regularly replace air filters to maintain clean airflow and avoid complications during applications.

- Calibration: Periodically calibrate systems to ensure electrostatic charging and temperature controls work effectively.

Trends in Powder Booth Technology

As the automotive industry evolves, so does the technology behind powder booths. Key emerging trends include:

1. Smart Technology Integration

Modern booths are now incorporating IoT devices, offering remote monitoring and control to streamline operations.

2. Improved Energy Efficiency

Advancements in energy-saving designs contribute to lower operational costs and a lesser environmental footprint.

3. Eco-Friendly Powder Coatings

With a growing focus on sustainability, manufacturers are developing powder coatings that are even less harmful to the environment.

Conclusion: Invest in Your Future with Powder Booths

For businesses in the automotive and paint sectors, investing in a quality powder booth represents a commitment to quality, efficiency, and sustainability. As industries worldwide continue to seek better solutions to enhance their production processes, powder booths provide a competitive edge that cannot be overlooked. Companies like Autocoat India can significantly benefit from adopting advanced powder coating techniques that promise durability and an impressive finish, ultimately leading to increased customer satisfaction and loyalty.

Call to Action

If you are ready to elevate your automotive painting operations, consider investing in a powder booth that aligns with your business needs. Contact Autocoat India today to learn more about how our solutions can transform your production line and provide the high-quality finishes your customers expect.