The Ultimate Guide to Vacuum Pump Check Valves

The vacuum pump check valve is a vital component in many industrial systems. They play a crucial role in ensuring the proper functioning of vacuum systems, thereby affecting overall efficiency and operational safety. In this comprehensive guide, we will delve into the various aspects of vacuum pump check valves, including their types, functions, benefits, and selection criteria. By the end, you will understand why these components are indispensable in various applications.

Understanding Vacuum Pump Check Valves

A vacuum pump check valve is designed to allow the flow of air or gases in only one direction while preventing backflow. This feature is essential in maintaining the integrity and efficiency of vacuum systems. Without a proper check valve, the vacuum system can fail, leading to performance inefficiencies, potential damage, and increased operational costs.

How Do Vacuum Pump Check Valves Work?

The operation of a vacuum pump check valve is relatively simple yet highly effective. The valve typically contains a movable disc or ball that opens when the pressure from the pump exceeds the back pressure. This allows the necessary gases to flow into the system. When the pressure drops, or if there’s any back pressure from the system, the valve closes, preventing any reverse flow.

Types of Vacuum Pump Check Valves

There are several types of vacuum pump check valves, each suitable for different applications. Here are the most common types:

- Ball Check Valves: These valves use a spherical ball to block reverse flow. They are suitable for low-pressure applications.

- Disc Check Valves: Featuring a flat disc, these valves offer a low profile and quick response to pressure changes. They are commonly used in various industrial applications.

- Spring Loaded Check Valves: These valves utilize a spring mechanism to enhance sealing capabilities, providing reliable closure against backflow.

- Diaphragm Check Valves: Utilizing a flexible diaphragm, these valves are great for applications needing chemical resistance or for handling corrosive fluids.

- Membrane Check Valves: Often used in conjunction with rubber membranes, these valves ensure proper sealing in vacuum systems.

Benefits of Using Vacuum Pump Check Valves

Incorporating a vacuum pump check valve in your system offers numerous advantages:

- Prevention of Backflow: Ensures that gases do not flow back into the pump, which can cause inefficiencies.

- Enhanced System Efficiency: By maintaining the desired pressure, check valves help improve the overall performance of the vacuum system.

- Reduced Risk of Damage: Protects sensitive components from reverse flow, minimizing maintenance costs.

- Increased Safety: Preventing backflow contributes to a safer work environment, reducing hazards associated with pressure loss.

- Versatility: Suitable for a wide range of industries, including manufacturing, food processing, and pharmaceuticals.

Where to Buy High-Quality Vacuum Pump Check Valves

When it comes to purchasing vacuum pump check valves, quality is paramount. At vacuum-presses.com, we offer a selection of high-performance valves designed to meet the specific needs of your vacuum systems. Whether you're looking for silicone membranes, rubber membranes, or vacuum system parts, you’ll find everything you need in one convenient location.

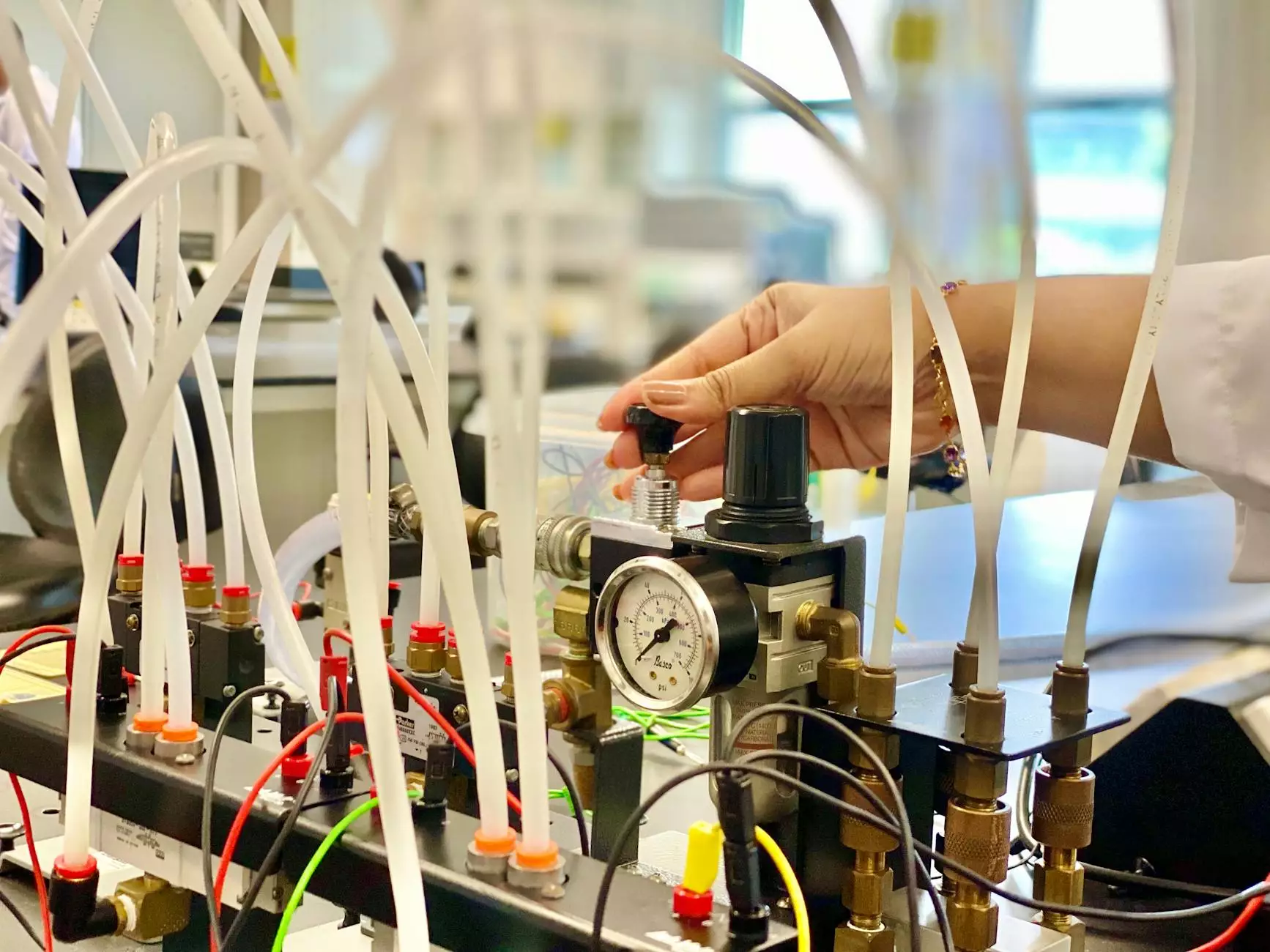

Vacuum System Parts: Essential Components for Optimization

In addition to vacuum pump check valves, maintaining a well-functioning vacuum system involves several critical parts, including:

- Pumps: The heart of the vacuum system, crucial for creating the desired vacuum level.

- Filters: Protect pumps from particles that can cause wear or clogs.

- Regulators: Help control the vacuum pressure levels within the system.

- Membranes: Essential for sealing and controlling the flow of gases.

- Hoses and Connectors: Enable proper connections between components, preventing leaks.

Factors to Consider When Choosing a Vacuum Pump Check Valve

Selecting the right vacuum pump check valve for your application involves several considerations:

1. Pressure Ratings

Ensure that the valve can withstand the maximum pressure levels of your system. Look for valves rated above your operational requirements.

2. Material Compatibility

The materials used in the check valve must be compatible with the gases or fluids being handled to prevent corrosion and ensure longevity.

3. Flow Characteristics

Assess the flow rate requirements of your system and choose a valve that supports the necessary throughput without significant pressure drops.

4. Installation Space

Consider the available space in your setup. Some check valves may require more room for installation than others.

5. Maintenance & Serviceability

Opt for valves that are easy to maintain and service. This will help reduce downtime and extend the life of your vacuum system.

Conclusion

In conclusion, the vacuum pump check valve is a crucial component in the realm of vacuum technology. Understanding its function, types, and selection criteria helps ensure that your vacuum systems are operating at their optimal performance. By choosing high-quality components from trusted suppliers like vacuum-presses.com, you can enhance system efficiency, prolong equipment life, and maintain safety in your work environment.

As you explore the various options available in the market, keep in mind the specific needs of your applications. Whether you need natural rubber membranes, silicone membranes, or other vacuum system parts, a thorough understanding of each component's role will guide you towards making informed purchasing decisions. Start optimizing your vacuum systems today!